What Makes Boogey Lights® Different?

It's no secret you can purchase LED light strips just about anywhere. Do a quick online search and you'll find hundreds of companies selling them often for a fraction of the price of Boogey Lights. And at least at first glance, they look very similar. Most are sold on rolls of 5 meters (196") in length. Most have clusters of 3 LEDs mounted to a strip of printed circuit board. Most also stick-on in some way, often with double-sided tape. The reality however is that not all LED lighting systems are created equal. Far from it. Truth is, the vast majority of LED strip lights being sold today are re-purposed residential lighting LEDs designed for use indoors on cabinets, under-counter-tops, behind entertainment centers and the like. These lighting systems work well indoors when attached to stationary objects. They are however poorly suited for outdoor applications subjected to harsh outdoor conditions when mounted on vehicles that move, flex, vibrate, contract and expand. The LEDs and electronic components we use are of the highest quality manufactured to our specifications for Boogey Lights® only. We source our product components directly and we assemble them right here in the United States. No middle man. No jobber. No distributor. Our products are not cheap, mass-produced knockoffs often found on discount marketplaces. Sorry - a $60 (or less) LED strip purchased on your favorite online marketplace is not even close in terms of quality, construction, capability or brightness. Anyone claiming otherwise simply hasn't done their homework.

Read on if you want to learn more about what makes Boogey Lights® LED lighting products different than anything on the market.

Boogey Lights® manufactures high-performance LED lighting systems for accent lighting applications. We design our lighting systems so the LED light fixtures can't be seen. Only the glow from the lights can be seen. That's why we don't make 'chicken lights', running lights, marker lights or similar lighting found on motor vehicles. With only a few exceptions, our led lighting systems are designed to be hidden; completely out of view. When installed properly, you'll only see the glow from a Boogey Lights® LED lighting system.

TEN Reasons Why BOOGEY LIGHTS® are Superior

Difference #1

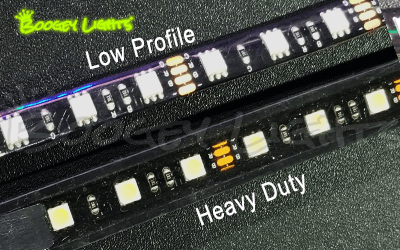

Two Options: Low Profile and Heavy Duty LEDs

Boogey Lights® produces two types of LED light strips - one for recreational, light duty applications and one for commercial, heavy duty applications. Both styles use the same custom made, 2 oz copper PCB, clear poly-urethane UV resistant coating and super-bright tri-chip 5050 LED components with more LEDs per foot than any other product on the market. The difference is the HEAVY DUTY LED strips are encased in an industrial grade black flexible PVC which make them ideal for tough outdoor and commercial applications where the light strip might be subjected to direct impact or corosive road chemicals. The flexible PVC used on the Heavy Duty LED strips provides an extra, dual layer of protection above and beyond our already tough low profile led strips.

For recreational and light duty applications where the LED strip is unlikely to receive a direct strike from road debris or be exposed to corosive road chemicals, we recommend our LOW PROFILE LED strips. Their low profile design makes them easy to fit into tight spaces and can be custom made to fit any length from 3" to 16'. Plus, they're incredibly bright; nothing brighter on the market. They're available in single color, dual color (7 colors + Amber) and multi-color (RGB, RGBW, RGBA, RGBWW) on white or black PCB.

Our HEAVY DUTY LED strips are available in five fixed lengths that contain between 15 and 75 high-intensity super-bright 5050 tri-chip LEDs. The PCB is black with 1.2mm of 3M® VHB tape affixed to the back. Additionally, the end caps have a screw hole allowing these strips to be screwed to the mounting surface for additional holding power. No other product on the market matches these specifications for toughness and brightness. Available in single color, Dual Color (7 colors + Amber) and multi-color (RGB, RGBA) configurations and in five fixed length sizes. When installed according to our instructions using 3M Adhesion Primer, neither our Low Profile or Heavy Duty LED strips will come off unless you pull them off.

Difference #2

Specially Designed Printed Circuit Board (PCB)

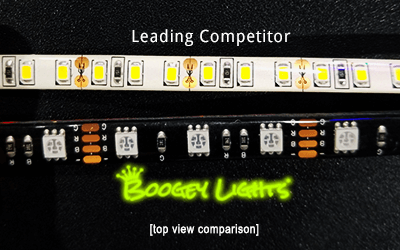

The PCB material we use is made specifically for Boogey Lights® LED lighting systems. You cannot purchase this PCB off-the-shelf. It isn't stocked by PCB manufacturers nor is it readily available for purchase anywhere. It's custom made just for Boogey Lights®. This is one of the reasons why we're one of the few companies who offers PCB colors in both white and black to better match the color of the surface it's attached to. Beyond the PCB color options however is the fact that our LED lighting products are mounted on PCB that has been specially designed with larger solder pads for the components. These larger solder pads allow for more solder to be used when securing the components to the PCB making it far less likely a component will easily separate from the PCB when under stress (a common problem with most every LED strip made today). Perhaps most importantly though is the fact that our LED lighting products use PCB containing two ounce copper weight instead of the standard .5 or 1 ounce copper commonly stocked by PCB manufacturers, available off the shelf. Why? Because two ounce copper PCB is thicker, tougher and more durable. PCB copper weight is the amount of copper present in one square foot of area. A two ounce copper weight equates to a PCB thickness of 2.8 mils. The thickness of the PCB is particularly important when used on vehicles that move, flex, vibrate, contract and expand. It's also important because it's the PCB that carries the electrical current to the individual LEDs mounted to the strip. Thicker PCB means less voltage drop across the strip which equates to brighter LEDs. Most LED lighting products use a low grade PCB of .5 ounce copper which is only .68 mils thick (see side by side comparison photo below). This thinner PCB works fine for stationary indoor applications but it's a bad idea for outdoor applications on vehicles that move, flex and vibrate. Boogey Lights® lighting products use PCB that is two to four times thicker. Little wonder even after a brief period of time competitor LED products sold today often fail within a short time frame and aren't nearly as bright as Boogey Lights®.

Difference #3

The Largest, Brightest LEDs Available

Just like PCB, the quality of each LED chip varies significantly based on the manufacturing process. And it's the LED chip that generates the light you see. LED chips are manufactured by various companies around the world with Japan being the recognized leader. The quality of the materials used is a major factor and one of those factors is the rare earth phosphor used in constructing the chip. Cheap LEDs are often made with low quality phosphor to reduce costs, but it also means dimmer and less reliable LEDs. Another factor is the power supply used. LED chips need to be driven with a constant current DC supply. This is accomplished with capacitors that are in-line with the LED chips. Low quality capacitors reduce brightness and life span. Presently, the 5050 LED chip is the biggest and brightest LED chip available which is all we use for our light strips. Most competitors use LEDs that are one-third or even one-half the size of ours. These include 2835, 3030, 3014, 2323 or even 1206 chips. Take a look at the top view photo above. You can see the difference. We also source our LED chips from the world's leading LED manufacturer who specializes in high-quality LED chips made with quality components. Yes, it costs more but if you light a strip of Boogey Lights® and place it next to any competitor's LED strip on the market today you'll quickly see the difference not only in brightness, but in clarity.

Difference #4

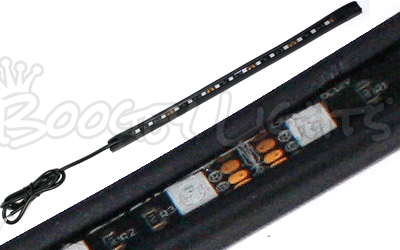

Hardwired Power Leads

The single most common point of failure in an LED light strip used outdoors is the point at which the power lead connects to the LED strip. Our power leads are hardwired to the end of the LED strip and sealed with not one but two layers of epoxy heat shrink. And, for many of our lighting applications we include 15' of power lead cable (we also offer custom lengths if you need them). The leading competitor by comparison provides just a few feet of power lead and uses a flimsy plastic barrel type connector that will either be hanging outside or you'll need to drill a sizable hole through the side of your vehicle to get power. That flimsy connector also has a tendency to vibrate loose as the vehicle moves down the road. Plus, the connector design allows moisture to easily seep into the connection corroding and shorting out the lights over time. Our hardwired methodology avoids these problems.

Difference #5

It's the End Result that Matters. Not How Fast it can be Installed.

Unlike every other lighting product on the market, our primary focus is on producing a lighting system that absolutely floods the entire area with an even, consistent glow of light and does so in a way that the LEDs and related cabling can't be seen. This is why our lighting systems have more LEDs per inch than any other product on the market. Secondarily, we design our lighting systems to minimize possible points of failure. This is why all of our power leads are hard-wired, soldered directly to the LEDs. There are no bulky connectors. No push pins. No proprietary extension cables. No light pods daisy chained together. No repeaters. Nothing to fail. Our sole focus is on how the end product looks on the vehicle after it is installed. Everything else is secondary. By comparison, every other competitor places top priority on ease of installation; eg. "plug-n-play". We believe this approach to be fundamentally flawed. Why? Because it sacrifices full lighting coverage in favor of a faster, easier installation. Placing the priority on 'plug-n-play' forces the use of bulky push-pin connectors, wiring harnesses, light pods, repeaters or multipliers and lots of extra specialized cabling. Doing so adds significant cost while contributing absolutely nothing to the end result you see. Plus, all these plug-n-play components introduce additional points of failure. Most importantly, the design means fewer LEDs and thus, much less light. The result is clumps of light pods in some areas while leaving other areas dark. If sporadic, clumps of light is what you want, great! We however don't share that view. We make no apologies whatsoever that our lighting systems are not plug-n-play. Yes, Boogey Lights® take a little longer to install. We however think the results speak for themselves. Long after the joy of a quick install wears off, you'll be stuck with an inferior looking lighting system that's prone to component failures. If you want the brightest, most robust, longest lasting LEDs that will absolutely flood the entire area with light, Boogey Lights® has no equal - period.

Difference #6

Thicker Adhesive Back

The adhesive backing on Boogey Ligthts® LED light strips is the best available. We only use genuine 3M® products. Sadly, counterfeit products masquerading as genuine are widely used by many manufacturers in Asia to cut costs. 3M® is the "gold standard" when it comes to adhesive for a reason. Knock-off 3M® lookalikes have flooded the Asian market which are inferior with less holding strength. We also add extra thickness - at least 3x thicker than the leading brand. Like a shock-absorber, the thicker adhesive backing absorbs much of the lateral side-to-side movement when the vehicle vibrates and flexes going down the road. Without that extra thickness the LED strip, PCB, solder joints and LEDs have to absorb the vibration and flexing directly. It doesn't take long before that vibration and flexing damages the strip.

Difference #7

3M® Adhesion Primer Included in our Light Kits

Look on most any website selling LED light strips today and if they're honest, one of the top complaints from consumers is their LED strips fall off. They don't stay stuck. There's a reason why. Cheaper brands don't include 3M® Adhesion Promoter with their kits. Of course any company selling stick-on LED lights know the importance of using 3M® Adhesion Promoter in the installation process but to cut costs, they leave this important detail out. Many don't even mention the need to use it anywhere in their documentation. So consumers buy the product based on price only to find out later the light strips fall off. This of course makes the lights worthless. At Boogey Lights® we don't do business that way. Our LED lighting kits include 3M® Promoter because in our view, it's an essential ingredient in making sure the LEDs work and perform as advertised. Sure, it costs more but it's also the reason why our light strips stay stuck!

Difference #8

Superior Controller Technology

Boogey Lights® offers a wide variety of LED controller devices; both wired and wireless - even use your smart phone. We are the only company that offers LED controllers specifically designed to work on large format vehicles capable of powering as many as 3000 LEDs and drawing as much as 40amps. The leading competitor by comparison has a single option with a maximum capacity of 300 LEDs. If you want to expand their system, you have purchase 'repeaters' or 'multipler' boxes which add cost, complexity and more points of faiure. In addition, all Boogey Lights® RGB and RGBx LED strips are COMMON CATHODE strips with the controller technology being POSITIVELY SWITCHED. This means that Boogey Lights® LED strips share a common ground. The controller switches on/off the positive (hot) side of the circuit similar to how every motorized vehicle in the United States is wired. Just like your car, Boogey Lights® LED strips are only energized with power when they are in use. Without getting into the electrical weeds the advantage of this design is that it is more robust, more efficient, will last longer and provides a brighter glow. It also means there is less chance of the LED strip or controller shorting out, making it safer. Of course it costs more to build a controller that switches the positive side of the circuit instead of the negative. That's why most competitors use negatively switched controllers with common anode LED strips. Little wonder common anode LEDs and negatively switched controllers are the default circuit design mass-produced and used throughout Asia.

Difference #9

Superior Customer Service

Take a moment to read some of our product reviews. Go ahead. Do it now. We'll wait. Don't just read the ones you see here on our website either. Search the internet. Look at some of the candid consumer comments. While no company is perfect, we think you'll find a common thread in our product reviews: 1) superior product quality and 2) outstanding customer service. Of course the fact that we've been in business since 1989 helps but we don't think you'll find any serious competitor who comes close to the quality of our products and our customer service. Perhaps best of all is that all of our customer service and support is done out of our Florence, KY based facility where we offer toll free 800 support, email support and text support. By comparison, the leading competitor is 100% made in Asia and sold to the US market by a company in Canada that doesn't even offer telephone support.

Difference #10

Designed, Assembled and Supported in the United States

Perhaps the #1 difference is Boogey Lights® products are Designed, Assembled and Supported right here in the UNITED STATES. A quick review of competing LED lighting products today reveals none of these products are 'Made in the USA'. In fact every competitor we're aware of are made overseas with very little, if anything, being done in the United States. For example, the leading RV awning light sold online and by major RV dealers across the country is 100% produced in Asia - even the printing and packaging. The product is then sold to the US market by a Canadian company. Not even the support is done in the United States. And yet this product is the #1 selling RV awning light in the country. You'll find similar parallels with LED lighting products offered for sale to the heavy duty truck market. We think this is a problem. This is why we go to considerable expense and effort to develop, produce and support as much of the products we offer from within the United States as we can while still being competitively priced. For more detail on this Made in the USA issue, click here.

** BONUS ** Difference #11

CANDID PHOTOS SUBMITTED BY REAL CUSTOMERS OF REAL INSTALLATIONS

Take a look at the product and advertising photos of competitor lighting systems; particularly the large RV and Semi-Truck lighting systems. Take a close look. Notice anything about those photos? Do they look too pefect? Or too polished? Perhaps even photo-shopped? Sadly, that's the case with many of the photos competitors are using to promote their lighting products these days. They'll showcase one single photo of an unknown brand RV against an unknown backdrop with full perimeter under-glow lighting making a perfect circle of glowing light around the RV. Clearly, this photo isn't genuine. It's fabricated. It's fake. Anyone who spends more than a few seconds looking at the photo notices. One has to wonder why, if their lighting systems are everything they say they are that they aren't showcasing real world photos from real customers using their product? Why go to the trouble of computer generating an image? Just use a customer submitted photo of your product installed on their RV. Very simple.

Now, take a look at the literally hundreds of photos on our website and in our advertising of Boogey Lights® lighting systems out in the wild. Look at the photos on our home page. Look at the photos on our product pages. Look at the photos in our photo gallery. Look at the photos we post on Facebook, Instagram and Youtube. Not only do we have multiple photos of our lighting products being displayed on different makes/models/types of vehicles used in a wide variety of environments, without exception, all of our lighting system photos are of REAL customer installations. In most cases these photos are submitted by the customer directly. And, they're using the camera on their mobile phone to take the photo. No professional studio photography. No fancy backdrop. No staging, No photo-shopping. Just real, everyday customers showing off their Boogey Lights® installed on their vehicle out in the wild.