Cargo and Utility Trailer LED Interior Lighting

Super Bright Interior Work Space Lighting

Great for Cargo Trailers, Utility Trailers, Car Haulers, Race Trailers and Food Trucks Too!

Super bright 12vdc workspace lighting is here! Our impressively bright surface mounted high-performance LOW PROFILE flexible LED strips are ideal for cargo trailers, utility trailers, car haulers, racecar trailers and food trucks too. With more super-bright LEDs per inch than any other surface mounted LED strip on the market, our flexible LED strips are built tough for mobile workspace lighting applications.

READ THIS BEFORE ORDERING!

Installation? Whomever is doing the installation must be willing to read the directions. Please read that sentence again. While we have some How-To-Videos that provide general guidance, they are not a replacement for the written documentation. Yes, we realize that's not what folks want to hear but reading the installation directions is absolutely essential if you want your light kit to fit and work properly - and last too! Probably 90% of all calls we recieve about this product are the result of consumers who didn't read the directions. Seriously, take our advice and read the directions. We promise, you'll be glad you did.

FAQS | Frequently Asked Questions

While we encourage you to read all of the information presented on this product page (including the information on the navigation tabs), below are some of the most frequently asked questions we get about this product. In all cases, the answers to these FAQs will refer you to other sections of this product page for more details on the topic.

How is this lighting system mounted?

How difficult is this light system to install?

NOTE: You must have an understanding of 12vdc power. An essential skill with installation of any Boogey Lights® LED products is knowing how to correctly wire the product to a 12vdc circuit. This includes understanding the importance of having a properly sized fuse at the power source, polarity, how to properly seal an electrical connection, using properly sized wire gauge for the load, measuring voltage and measuring the additional amperage draw you're adding. This is especially true for this product. Be sure to read the information about amperage draw prior to designing your lighting system. If you are uncertain or unfamiliar with any of these concepts, we urge you to ask someone who has the knowledge to assist you. Electricity is unforgiving.

Will these lights work on a V-Nose trailer?

What are the power requirements?

Where can I find a diagram of the typical installation layout?

PRODUCT HIGHLIGHTS

While Single Color dimmable WHITE LEDs are by far the most popular for workspace applications, our surface mounted LED strips are available in additional solid colors including RED, GREEN, BLUE, ORANGE. In addition, we offer an RGB multi-color version where you can change the color using a wireless remote control (or your smartphone and our free Android or IOS APP). Built with two ounce copper PCB, the brightest 5050 LEDs available and 1.2mm of genuine 3M® VHB double sided tape, these LED strips are super easy to install yet made tough for motor sports applications. They're available on either white or black PCB. While our high-performance flexible LED light strips are available in varying lengths we've put together this interior led light kit to provide the components needed to fit some of the most common sized cargo/utility trailers from 16' to 36'. All flexible LED strips come on a roll with a 15' power lead attached to them. Click on the SPECS tab of this product page to see detailed specifications along with close up photos of the LED strips used for this product.

Single Color vs RGB (Multi-Color)

While most mobile work space lighting is white, nothing says it has to be that way. With an RGB led strip you can have the best of both worlds. With RGB, you can control your lights with a wireless remote control OR your smartphone and our bluetooth APP. One of the colors available is WHITE ... but so too are many other colors (up to 16 million if you want to get technical). One important caveat .... RGB white is not as bright as Single Color white. The reason is that in an RGB LED there are three diodes: red, green and blue. Mixing equal parts red + green + blue creates the color white. In a single color LED, all three diodes are the same color. So in a single color white LED, there are three white LEDs which is much brighter than an RGB led mixed to show white. If you're for the absolute brightest white you can get for your trailer, go with single color white. If however you want to be able to change the colors from time to time, go with RGB. Just be aware that the RGB version of 'white' isn't as bright as the single color version.

Multi-Color RGB 3 Relay Option

If you order multi-color RGB LEDs you'll see the option of adding 3 heavy duty relays to your order. These 3 relays are needed if you want the flexibility of a multi-color RGB LED light strip but also would like to be able to turn on just WHITE using your trailer's wall light switch. Scroll down further on this product page and you'll see a more detailed explanation of this configuration with a detailed wiring diagram.

Got a V-Nose Trailer?

This light kit works just as well on v-nose cargo trailers. The reason is that our leds are super bright. Unless you have a special application where you need a higher concentration of light in the v-nose area of the trailer, two LED strips down each side of the trailer as shown in our diagrams will be more than adequate to flood the inside of the trailer; including the v-nose section. If however you want to add an additional 2', 3' or even 4' LED strip just for the v-nose area, you can order that extra strip using our LOW PROFILE LED STRIP product.

SWITCHING OPTIONS

Single Color: Most mobile work space lighting is single color white because it's the brightest light available. For single color lights you're going to need an on/off switch at minimum. Some prefer to add a dimmer switch too. It ultimately depends on your setup. We offer two optional switches for single color: on/off wireless (with 40 amp relay due to amperage) and a wired on/off dimmer (black and white finishes). Some trailers may already have a switch installed in which case you may be able to use the existing light switch. Just make sure you confirm amperage ratings. A single 16' LED strip containing 300 leds will pull about 3.25amps on full brightness white.

RGB / Multi-Color: For RGB led lighting an LED Controller is needed to operate the lights. The controller is what operates the lights. If you're purchasing RGB leds, you'll need to also purchase an LED Controller from the available list of LED Controllers. Make sure you select the LED Controller that matches the capacity rating for the number of LEDs you're purchasing. All of the RGB controller options presented are our latest GEN2 (G2) LED Controller. You can find more detail about these new GEN2 LED Controllers by clicking on the CONTROLLERS navigation tab appearing on this product page.

In addition to providing a wireless on/off capability, the LED controllers offered allow you to control your lights with your Bluetooth 4.0 enabled smart phone and our free smart phone APP (Android and IOS) OR your choice of the included RF wireless remotes. With the included RF remote you can change between 7 colors and functions of on/off, blending, strobing, breathing, flashing, fading and dimming. You can also use your Bluetooth enabled smart phone to create that custom look with over 16 million different color combinations plus three pre-sets. The BLUETOOTH navigation tab on this product page provides significantly more information about the Bluetooth integration.

PCB COLOR?

Surface mounted LED chips are mounted to a Printed Circuit Board (or PCB for short). The color of that PCB makes a difference in how the finished installation looks in the daylight. Our LED light strips come in two versions to match the surface the strip will be attached to. For interior lighting it's usually not all that important but for exterior lighting (e.g. RV awning light) if you have a light colored RV, you will probably want to order the WHITE PCB light strip. If you have a dark colored RV, you will probably want to order the BLACK PCB light strip.

FEEDER CABLE OPTION

Do you need feeder cable? Maybe. How much feeder cable do you need? We don't know. Depends on your ligting configuration and your wiring plan. Feeder cable is used to connect the various LED light strips to the switching mechanism (and power source). How much cable is required for your particular installation depends on where you are mounting the LED strips and where your switching mechanism is (along with your power source). Each LED strip in this light kit comes with a 15' power lead already permanently attached to the LED strip itself. So you may not need any feeder cable. We always suggest creating a wiring plan for your installation and then based on that plan, estimate how much feeder cable you need. Note that feeder cable is just 12vdc stranded copper wire. Typically 18awg or 20awg is what we use. It's available at just about any hardware or big box store in the country. Fire alarm cable is probably the most common. We offer it for sale as a courtesy to our customers but you can usually find it locally for less money. For single color LEDs you'll need 2 conductor. For RGB you'll need 4 conductor. For RGBx you'll need 5 (or 6) conductor.

INSTALLATION ALERT

We suggest mounting the LED strips in this kit to plastic or aluminum flat stock (or something similar) and then mounting that assembly to the trailer. Do not mount the LED strips directly to the trailer's existing surface. The reason is that many cargo trailers don't have finished interiors and those mounting surfaces are prone to flexing/movement as the trailer moves down the road. If you mount the LED strip directly to the existing surface, the LED strip is likely going to fail prematurely due to the flexing of that surface. Mounting the LED strip on another surface such as plastic flat bar and mounting the assembly to the trailer will isolate the LED strip and protect it from that flexing. The Aluminum Channel mounting option offered below is a great way to solve this problem. LED strips that fail when mounted directly to the trailer's inside surface are not covered under warranty.

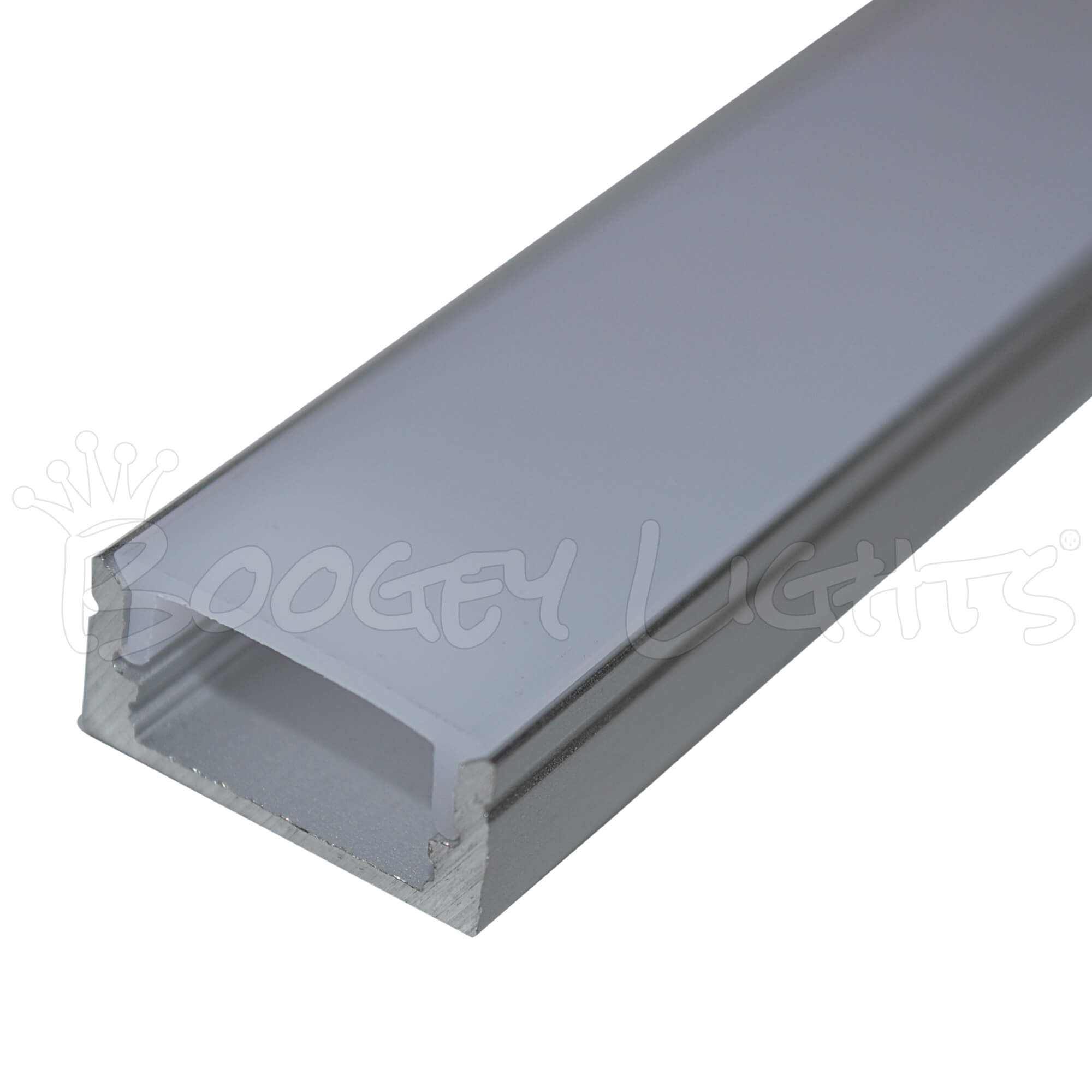

ALUMINUM CHANNEL OPTION

For those who want to dress up the installation, we offer aluminum channels and plastic difusers. They make for a professional looking installation. The channels typically are riveted (or screwed) to the ceiling (or side walls) of the trailer and then the LED strip attaches to the channel with the difuser snapping in over top. If you select YES -- Add Aluminum Channel w/Diffuser (default is NO), your light kit will include enough channels plus plastic diffusers for the lighting configuration you select. Note that some cutting of these channels will be required. These aluminum channels and plastic diffusers are 78" long so you'll need to mount multiple channels end to end. You can read more about these channels by visiting this ALUMINUM CHANNEL product page.

VIDEO: HOW TO ADD OVER-HEAD LIGHTING

In this 2 minute video we show you how we install Boogey Lights® LEDs for over-head lighting on this cargo trailer.

USING RELAYS WITH RGB TO CREATE WHITE USING AN ON/OFF WALL SWITCH

If you want the flexibility of a multi-color RGB LED light strip but also would like to be able to turn on just WHITE using your trailer's wall light switch you can do it using 3 relays. You'll need to select the RGB Multi-Color LED color option and then select any of the available G2 (GEN2) LED controllers offered in the drop down. You'll notice too when you select the RGB LED Color, you'll be presented with the option of buying the 3 heavy duty relays (you can also buy these relays locally at any auto parts store). Click the button below for the wiring diagram. You can also DOWNLOAD THE WIRING DIAGRAM.

USING 3M ADHESION PRIMER

To achieve the full adhesive strength of the 3M® tape affixed to the back of each strip 3M® Adhesion Promoter (aka Primer) must be applied to the mounting surface first. This is an important step to ensure a secure bond. The 3M® Adhesion Promoter creates a chemical bond between the tape and the mounting surface such that the LED strip will stay stuck (at least until you decide you want to remove it). Using any other solvent such as rubbing alcohol or acetone is not the same thing as using 3M® Adhesion Promoter. While these solvents will help clean the surface, they do not prime the surface. There is a difference. 3M® Adhesion Promoter is included with this kit although you may elect to purchase more if you'd like.

OTHER ITEMS YOU MAY NEED

No two installation scenarios are the same. Not everyone shares the same installation quality goals. Some folks are OK with twisting wires together, others want to solder them. Some folks are OK with running wires where they may be seen or unprotected to save money/time, others want a tidy, clean install without any wires showing. Some folks are OK with mounting their LED strips to whatever surface they can find, others want to take the time necessary to build out appropriate mounting surfaces to provide the best lighting effect on their vehicle. The point is it's not possible to provide all the materials necessary for all installation scenarios and quality goals. Our light kits provide the essential components needed for a high-quality, functioning lighting system. Installation of our light kit to your specific vehicle may however require additional items to make it look and fit the way you want. This is particularly the case with electrical wiring and mounting of LED strips. Before proceeding with your installation we suggest you consider THESE OTHER ITEMS.

Will Boogey Lights® Work with Other Brands?

The short answer is probably not. All Boogey Lights® RGB LED strips are COMMON CATHODE LEDS. They share a common ground and will only work with positively switched controllers. Most LED strips on the market today are COMMON ANODE because the controller technology used to power them is less expensive to manufacture. However they're not nearly as bright and are an overall inferior design when compared with COMMON CATHODE LEDs. For more information, click the button below.

WARRANTY INFORMATION

Boogey Lights® Low Profile Hi-Intensity Surface Mounted LED light strips are used in a number of Boogey Lights products for a variety of vehicle applications (including this product). Where and how these light strips are installed make all the difference in their durability and thus, our warranty. For this reason the duration of the Boogey Lights Low Profile Hi-Intensity LED Light Strips original owner warranty varies based on the vehicle application, use and installation types.

- Recreational Applications: RVs, Motorcycles, Golf Carts: 3 years

- Cars/Pickup Trucks/Off-Road: 1 year

- Marine / Fresh Water: 3 years

- Marine / Salt Water: 90 days

- Food/Cargo Truck/Trailer, Other Light Duty Commercial Use / Installation done by Boogey Lights technicians in Florence, KY: 3 years

- Food/Cargo Truck/Trailer, Other Light Duty Commercial Use / All other installation types: 1 year

- Heavy Duty Truck and/or Trailer Commercial Use / Installation by Boogey Lights technicians in Florence, KY: 1 year

- Heavy Duty Truck and/or Trailer Commercial Use / All other installation types: 90 days

Configurations

Mobile Work Space Lighting Configuration Options

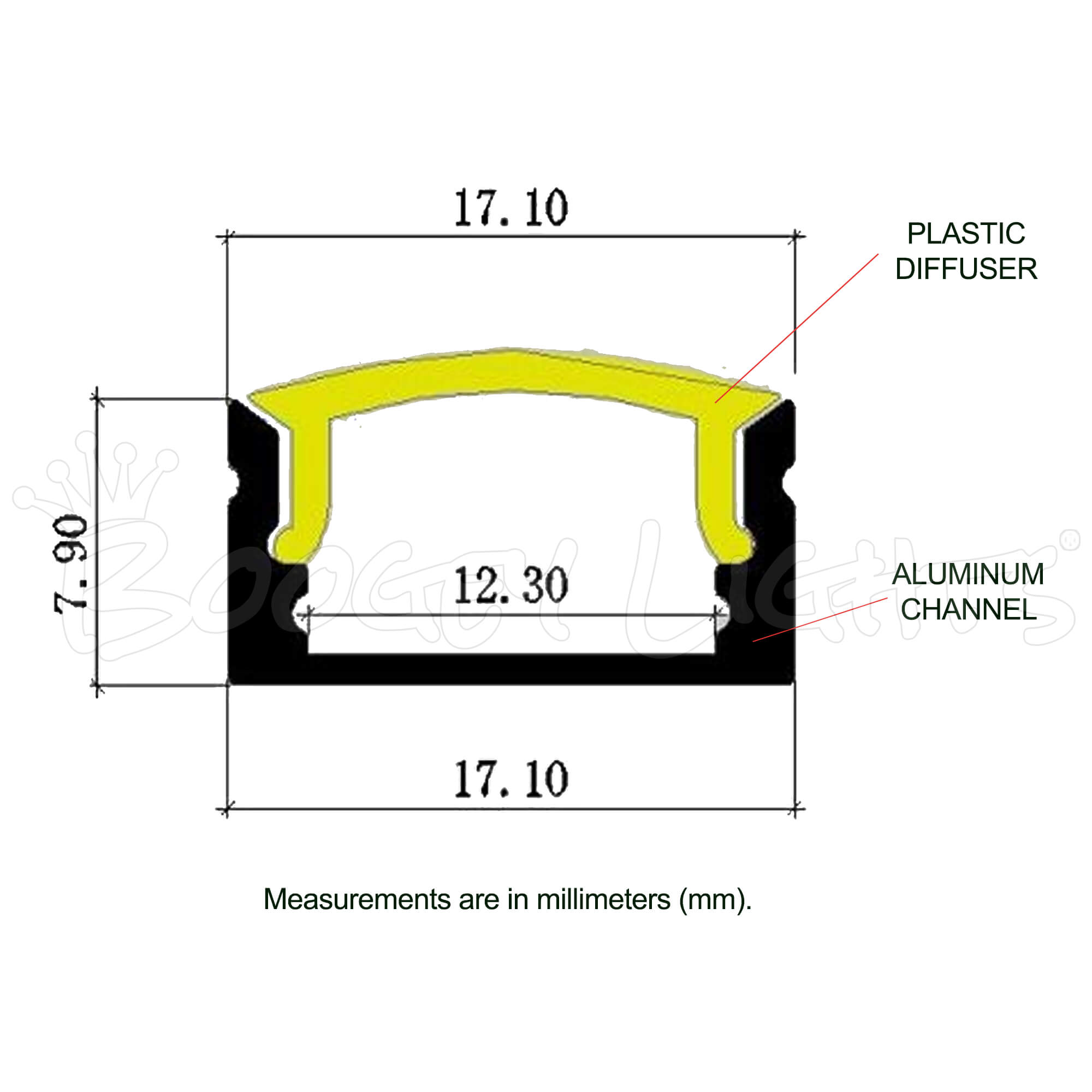

The default configuration is designed to provide two rows of LED lighting mounted either high up on the two longest side walls (towards the point where the side wall meet the ceiling) shining inward OR mounted to the ceiling itself 12 to 18 inches in on each side shining downward. For best illumination we recommend coverage of at least 80% of the trailer's length. So for example, if you have a 20' long cargo trailer, we'd suggest a minimum of 16' of LED lighting on each side (centered on the walls or ceiling ) to flood the area with light. Of course you can go the full length but in our experience it's not a requirement for adequate workspace lighting.

This LED Interior Light kit can be purchased in the following configurations:

- 8' to 12' Trailer: Two 8' LED strips (288 LEDs). One on each side.

- 12' to 16' Trailer: Two 12' LED strips (438 LEDs). One on each side.

- 16' to 20' Trailer: Two 16' LED strips (600 LEDs). One on each side.

- 20' to 24' Trailer: Four 10' LED strips (720 LEDs). Two on each side mounted end to end.

- 24' to 28' Trailer: Four 12' LED strips (875 LEDs). Two on each side mounted end to end.

- 28' to 32' Trailer: Four 14' LED strips (1020 LEDs). Two on each side mounted end to end.

- 32' to 36' Trailer: Four 16' LED strips (1200 LEDs). Two on each side mounted end to end.

All flexible LED strips come on a roll with a 15' power lead attached to them. Additional power lead feeder cable will in most cases be needed to complete the installation which is an option offered. For single color lighting you only need 2 conductor stranded cable (18 to 20awg is recommended) which you can usually purchase locally too.

IMPORTANT. You must have an understanding of 12vdc power. An essential skill with installation of any Boogey Lights LED products is knowing how to correctly wire the product to a 12vdc circuit. This includes understanding the importance of having a properly sized fuse at the power source, polarity, how to properly seal an electrical connection, using properly sized wire gauge for the load, measuring voltage and measuring the additional amperage draw you're adding. If you are uncertain or unfamiliar with any of these concepts, we urge you to ask someone who has the knowledge to assist you. Electricity is unforgiving.

Installation Overview

We suggest reviewing the installation documentation before purchasing so you know what's involved. You can DOWNLOAD the Installation Documents directly from this product page.

There is no set installation configuration. Your trailer and imagination are the only limits (well, and your budget). Here are some things to keep in mind when designing and installing our Hi-Intensity LED Strips.

- Our Hi-Performance LOW PROFILE LED strips can be cut every 3 LEDs to accommodate shorter runs. Just make sure you are cutting them where marked AND that you seal the cut end to keep moisture out.

- The maximum length of one Boogey Lights® Hi-Intensity strip is 16'. Multiple 16' strips CAN NOT be daisy chained together. If you want to do a run longer than 16', you can butt two strips together to get the desired length. For example, in the 20' trailer configuration, if you want full coverage of all 20', mount the two 10' LED strips end to end which gives the illusion of a full 20' strip. See diagram below.

- If you're using our mutli-color LED strips, the maximum number of 16' LED strips that can be powered at one time depends on which controller you're using. Our Heavy Duty controller will power at least six 16' LED strips. You might be able to get 7 depending upon your wiring. That said, it's possible to add additional controllers and manage those controllers with one RF remote. Lots of possibilities. The limitation ultimately comes down to your power source.

- If you're using our single-color LED strips, make sure you are not over-loading the circuit they are attached to. As with all lighting solutions, each LED strip should be properly fused. If for any reason there is a dead short in the strip, you want the power to that strip to be cut off to avoid over-heating and potentially burning.

- For multi-color LED strip installations, be mindful of where your power source is located as well as where you will be mounting the controller. The power lead for each Hi-Intensity strip needs to connect directly to the controller at your power source. Knowing where your controller will be mounted in relation to where the LED strip will be placed will determine how much power lead cable is needed on each LED strip.

- Boogey Lights® are native 12vdc devices. They require 12vdc to power them. Be aware however that because our lights are super-bright, they will consume more amperage than a traditional 12vdc LED. For example, a single 16' long LED strip with 300 single color white tri-chip LEDs which have 900 diodes and will pull about 3.2 amps on full brightness assuming 12.5vdc input. If the voltage input is 13.5vdc (common for many charging systems), that amperage draw jumps up to 3.8amps. So two of these LED strips would pull 6.4amps to 7.6amps. These numbers are for a 16' long setup. If you trailer is longer, those amperage numbers will increase. For trailers that are 20' or longer, having two 12vdc batteries in parallel just for the trailer is typical. Do not try to power these lights through the 5 or 7 way plug of your tow vehicle unless you know what you're doing. The amperage draw likely exceeds the tow vehicle's rated capacity. Also, having a way to charge those batteries is important too (e.g. generator, a battery charger or tow vehicle). Regardless, it's important when designing your lighting system you take these amperage calculations into consideration not just in terms of the battery capacity but also wiring and switching. If you are uncertain or unfamiliar with these concepts or how to do this we strongly urge you to ask someone who has the knowledge to assist you onsite. Electricity is unforgiving. You can view amperage data for all of our lighting products by clicking on the SPECS navigation tab on this product page. You can also DOWNLOAD THE AMPERAGE DATA CHART here.

- The only way to ensure the LED light strip stays stuck to is to make sure you prepare the surface in accordance with the directions. This includes making sure the mounting surface is smooth and free from oil, wax or other solvents. Our stand alone LED strips do not include 3M® promoter (aka "primer") so be sure you purchase some. It's absolutely critical the surface be prepared using this 3M® promoter and that you follow the directions provided with every light kit. For the power lead wires that feed the LED strip we include some extra 3M® tape and zip tie mounts. If you purchased an LED light strip that does not include this primer, we offer primer for sale individually or in cans.

- The length of power lead between the LED light strip and the power source absolutely impacts the brightness and power consumption of the light strip. This is an important concept to keep in mind when designing your setup. For power lead lengths longer than 15 feet (and less than 76'), we recommend using 20 gauge power lead wire which we offer for sale on our website. The lower the gauge number, the thicker the cable. The thicker the cable, the less power loss there is over longer distances.

- If you want a cleaner installation, we offer aluminum channels with optional diffusers that snap on top of the channels. The aluminum channels can either be screwed to the surface our you use 3M VHB tape (with promoter). Once the channel is mounted to the surface, the LED strip will then affix to the aluminum channel with the diffuser snapping in on top. It makes for a very clean installation. We offer a number of styles of aluminum channels for this purpose.

Installation Example

Important Note! We suggest mounting the LED strips in this kit to plastic or aluminum flat stock (or something similiar) and then mounting that assembly to the trailer. Do not mount the LED strips directly to the trailer's existing surface. The reason is that many cargo trailers don't have finished interiors and those mounting surfaces are prone to flexing/movement as the trailer moves down the road. If you mount the LED strip directly to the existing surface, the LED strip is likely going to fail prematurely due to the flexing of that surface. Mounting the LED strip on another surface such as plastic flat bar and mounting the assembly to the trailer will isolate the LED strip and protect it from that flexing. This Aluminimum Channel mounting option is a great way to solve this problem. LED strips that fail when mounted directly to the trailer's inside surface are not covered under warranty.

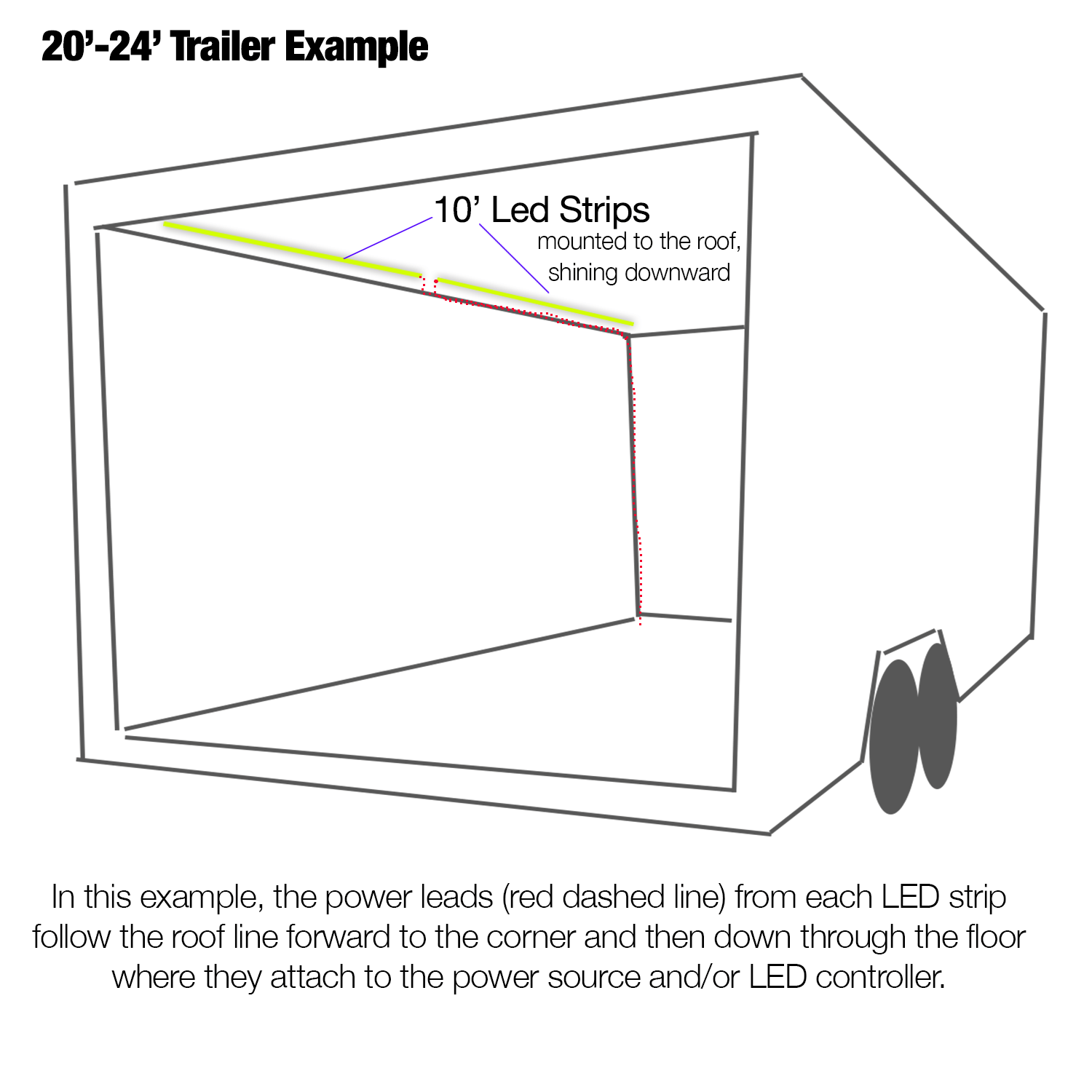

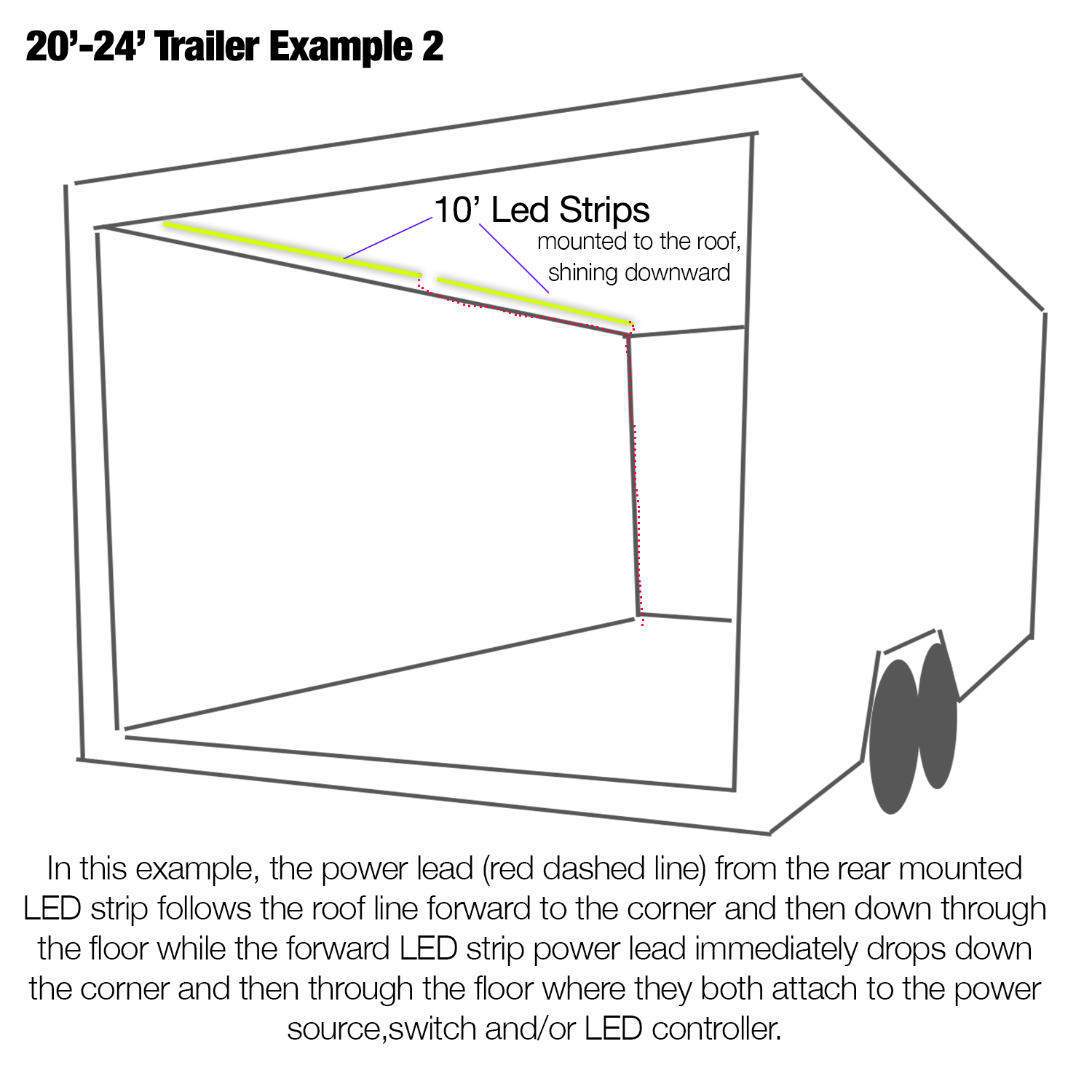

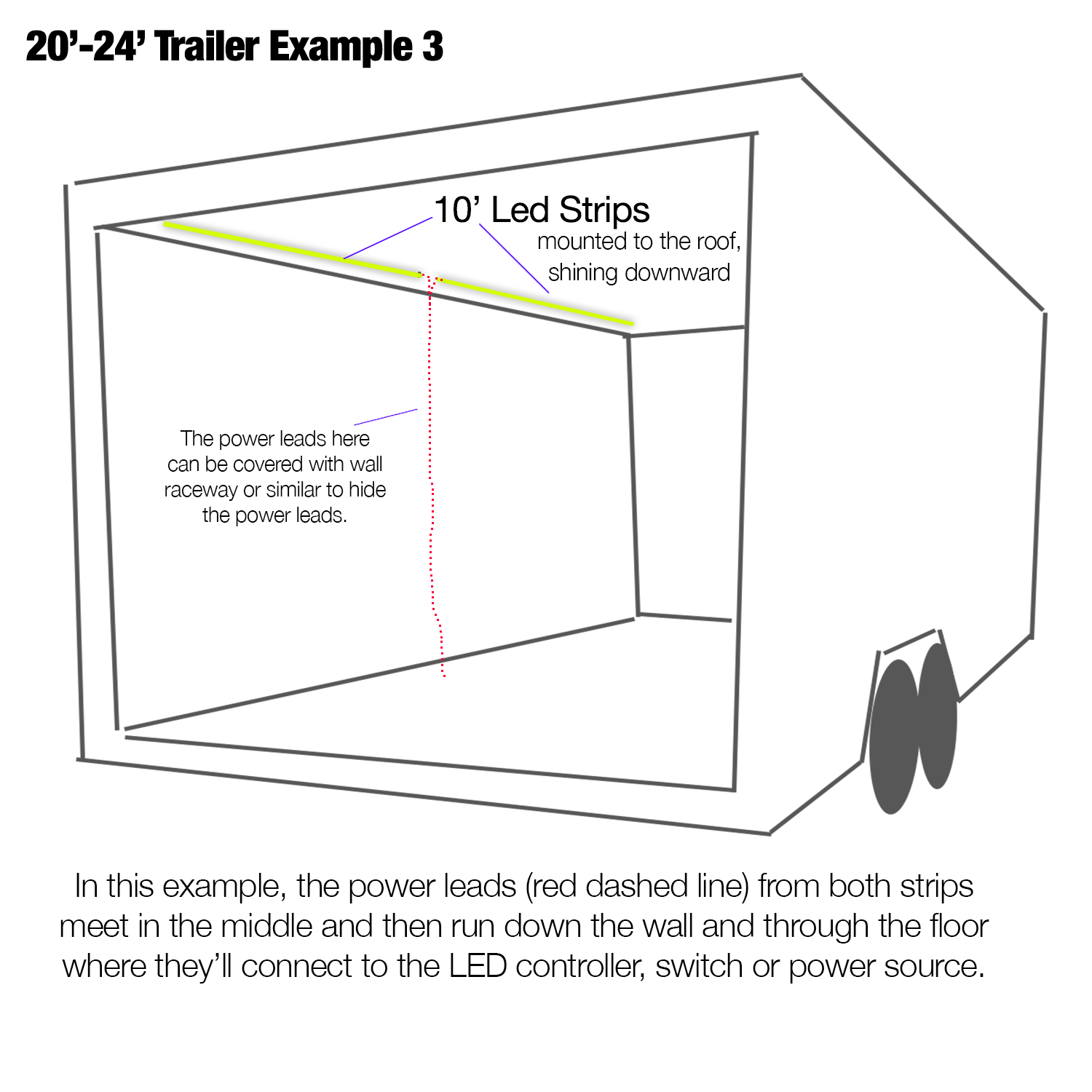

In this hypothetical example we have a 20' to 24' long cargo trailer. We want to install LED lighting on the roof shining downward. This diagram shows mounting and wiring placement. On each side of the trailer there are two 10' LED strips mounted to the ceiling about 12" from the side wall.The two power lead ends (the red-dashed line) come together in the middle (splice into one single cable OR continue as two separate cables) and then follow the roof line forward to the front wall where the power lead then drops down in the corner through the floor where it will connect to the LED controller, switch or power supply. Another way to do this would be to mount both LED strips with their power lead ends facing forward. The front LED strip would immediately drop the corner. The rear LED strips would follow the roof line up to the corner and drop down. Either method will work. Another option would be have both power leads meet in the middle (like our drawing shows below) but have them drop straight down to the floor instead of going forward following the roof line. In this scenario the power leads can be hidden with wall cable raceway. You could also us some corner duct wall cable raceway to hide the cables that run down the corner. To fasten the power leads along the roof line, we like to use 3M VHB tape (be sure to use 3M Adhesion Primer first) or zip tie mounts. There are a number of options to secure the power lead wire to the roof line. Of course you would need to repeat the same process for the other side of the trailer.

Installation Diagrams

Installation Video

In this 2 minute video we show you how we install Boogey Lights® LEDs for over-head lighting on this cargo trailer.

Using Relays with RGB to Create White using an On/Off Wall Switch

If you want the flexibility of a multi-color RGB LED light strip but also would like to be able to turn on just WHITE using your trailer's wall light switch you can do it using 3 relays. You'll need to select the RGB Multi-Color LED color option and then select any of the available G2 (GEN2) LED controllers offered in the drop down. You'll notice too when you select the RGB LED Color, you'll be presented with the option of buying the 3 heavy duty relays (you can also buy these relays locally at any auto parts store). Click the button below for the wiring diagram. You can also DOWNLOAD THE WIRING DIAGRAM.

Using 3M Adhesion Primer

To achieve the full adhesive strength of the 3M® tape affixed to the back of each strip 3M® Adhesion Promoter (aka Primer) must be applied to the mounting surface first. This is an important step to ensure a secure bond. The 3M® Adhesion Promoter creates a chemical bond between the tape and the mounting surface such that the LED strip will stay stuck (at least until you decide you want to remove it). Using any other solvent such as rubbing alcohol or acetone is not the same thing as using 3M® Adhesion Promoter. While these solvents will help clean the surface, they do not prime the surface. There is a difference. 3M® Adhesion Promoter is included with this kit although you may elect to purchase more if you'd like.

OTHER ITEMS YOU MAY NEED

No two installation scenarios are the same. Not everyone shares the same installation quality goals. Some folks are OK with twisting wires together, others want to solder them. Some folks are OK with running wires where they may be seen or unprotected to save money/time, others want a tidy, clean install without any wires showing. Some folks are OK with mounting their LED strips to whatever surface they can find, others want to take the time necessary to build out appropriate mounting surfaces to provide the best lighting effect on their vehicle. The point is it's not possible to provide all the materials necessary for all installation scenarios and quality goals. Our light kits provide the essential components needed for a high-quality, functioning lighting system. Installation of our light kit to your specific vehicle may however require additional items to make it look and fit the way you want. This is particularly the case with electrical wiring and mounting of LED strips. Before proceeding with your installation we suggest you consider THESE OTHER ITEMS.